We develop cutting-edge custom digital twin solutions that align with the forefront of advancements in the technology sector.

At NewSoft Sage, our Digital Twin technology offers a cutting-edge solution for businesses looking to bridge the physical and digital worlds. By creating a virtual replica of your physical assets, systems, or processes, we enable real-time monitoring, analysis, and simulation to improve efficiency, predict maintenance needs, and innovate product development. Our Digital Twin service transforms data into actionable insights, empowering your business to make informed decisions, optimize operations, and drive forward digital transformation.

Proof of Concept for short term capability validation (4 weeks) Consulting-led engagement, delivered as a short-term proof of concept to assist you in testing and validating Digital Twin functionality within a controlled, simulated environment. We will guide you through the entire process, from defining the scope, designing, implementing, testing, and documenting recommendations to support your pre-site and pre-production Digital Twin deployment.

Digital Twin POC for maximum efficiency

Get ahead of the competition with our state-of-the-art Digital Twin solutions. Say goodbye to simulation inaccuracies and hello to precise virtual representations. Contact us today to explore our Digital Twin (POC).

Assessment & Planning Sustainability

Current Infrastructure Evaluation: Conduct a thorough assessment of existing infrastructure to identify potential areas for digital twin implementation.

Use Case Identification: Identify specific use cases where digital twins can provide value, such as predictive maintenance, process optimization, or simulation.

Technical Feasibility Analysis: Assess the technical feasibility of implementing digital twins, considering data availability, connectivity, and integration requirements.

Digital Twin Development & Integration

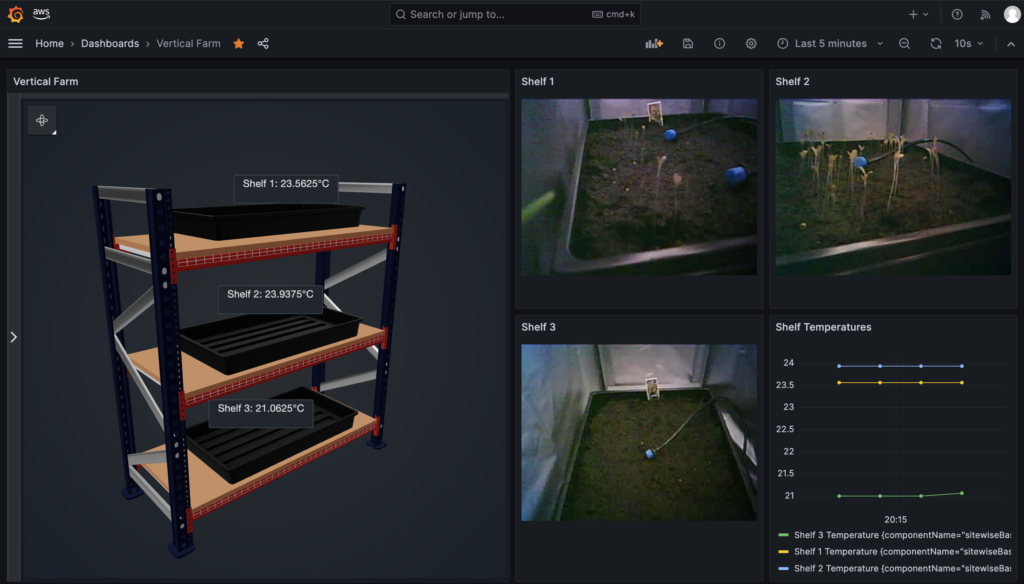

Model Creation: Develop digital twin models based on real-world assets or processes, incorporating relevant data and parameters.

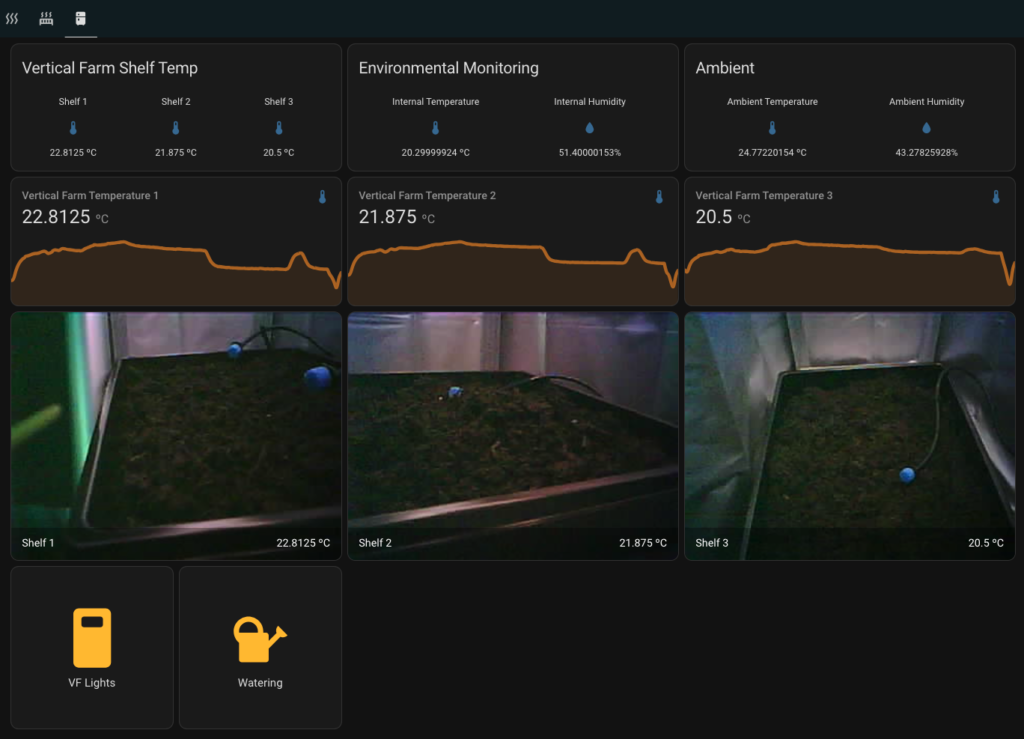

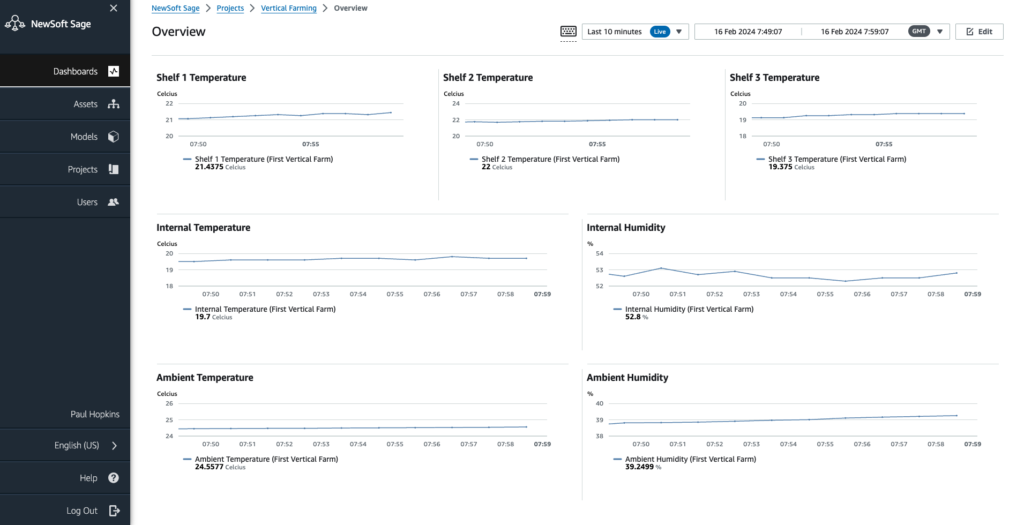

Integration with IoT and Sensor Networks: Integrate digital twins with existing IoT devices and sensor networks to enable real-time data collection and monitoring.

Simulation & Testing: Conduct simulation and testing to validate the accuracy and functionality of digital twin models.

Data Analysis & Visualization

Data Collection & Aggregation: Gather data from various sources, including sensors, IoT devices, and operational systems, for analysis within the digital twin environment.

Analysis & Insight Generation: Utilise advanced analytics techniques to analyse data and generate actionable insights for operational optimisation and decision-making. -

Visualisation & User Interface Design: Develop intuitive user interfaces and visualisation tools to facilitate interaction with digital twin models and insights.

Evaluation & Future Planning

Performance Evaluation: Evaluate the performance and effectiveness of digital twin implementations in addressing identified use cases and delivering value.

Stakeholder Feedback & Validation: Gather feedback from stakeholders, including operators, maintenance teams, and management, to validate the utility and usability of digital twins.

Future Roadmap Development: Develop a roadmap for scaling digital twin implementations across additional assets or processes, as well as for incorporating advanced features and capabilities.

The potential applications of Digital Twin technology have extended beyond traditional sectors such as manufacturing and IoT. Digital Twin can be integrated to facilitate swift decision-making and enhance user interactions by enhancing relevance at every touchpoint. Presently, Digital Twin technology is fostering the creation of novel insights and experiences, empowered by the robust cloud infrastructure.

_____________

Digital Twin technology in the manufacturing industry facilitates real-time data analysis and enhances automation throughout factory floor and supply chain operations. It enables the efficient management of large datasets, leading to enhanced product quality and decreased operational expenses.

_____________

_____________

_____________

_____________

Digital Twin technology in the agriculture and farming industry facilitates real-time monitoring of crop health and livestock conditions, optimizing irrigation, fertilization, and pest control. It also enables the deployment of autonomous farming machinery, enhancing operational efficiency and sustainability.

Unlock the power of digital twins across diverse industries with our cutting-edge solutions. Whether it’s optimizing crop yields in agriculture, enhancing customer experiences in retail, streamlining operations in manufacturing, ensuring efficient resource management in utilities, or beyond, our digital twin system revolutionizes how businesses operate. Explore real-time insights, predictive analytics, and tailored solutions through our intuitive dashboard interface. Witness seamless integration and scalability in our architecture, empowering your organization to thrive in the era of digital transformation. Experience the future of industry with our comprehensive digital twin services.

Order a free consultation – our experts will select the most effective solution

A Proof of Concept (PoC) is a preliminary demonstration that demonstrates how feasible and viable a proposed solution or technology is. Businesses can make informed decisions before full-scale implementation by validating ideas, assessing risks, and evaluating risks. Our PoC service, which is delivered within four weeks, provides a fast yet thorough evaluation of AI solutions customized to your specific requirements, reducing risks and speeding up innovation.

We offer comprehensive support from our team of AI specialists during the Proof of Concept process. Starting from the initial scoping and data analysis, we will work closely with you to ensure transparency, collaboration, and successful outcomes.

Upon successful completion of the Proof of Concept, we provide comprehensive insights, recommendations, and next steps for further development or implementation. Whether you choose to proceed with a full-scale deployment, refine the concept, or explore alternative solutions, our team remains committed to supporting your journey towards realizing the full potential of AI technologies.

If you're exploring new technologies, validating hypotheses, or seeking to mitigate risks before investing in a full-scale implementation, a Proof of Concept can be a valuable first step. Our team can assess your project requirements, objectives, and constraints to determine the most appropriate approach and provide tailored recommendations for achieving your goals effectively and efficiently.

Implementing Digital Twin technology enables real-time monitoring, predictive maintenance, and performance optimization across your operations. By creating virtual replicas of physical assets or processes, businesses can enhance efficiency, reduce downtime, and unlock new opportunities for innovation.

Digital twins enable real-time monitoring, analysis, and optimisation of assets and processes, leading to improved operational efficiency and performance.

By simulating real-world conditions and predicting asset behaviour, digital twins support proactive maintenance strategies, reducing downtime and maintenance costs.

Embracing digital twins demonstrates Newsoft Sage's commitment to innovation and differentiation in the industry, positioning the company as a leader in digital transformation.

Copyright © 2023 Newsoft Sage | Powered by Softrobo

PRIVACY POLICY| SITEMAP

Copyright © 2023 Newsoft Sage | Powered by Softrobo